Cofra has a long track record in the field of vacuum consolidation. We have multiple vacuum consolidation systems within our range of techniques, amongst which Beaudrain, BeauDrain-S and the traditional vacuum consolidation method using a synthetic liner. All concepts, except for the BeauDrain system which uses an in-house developed special plough, are installed by using our own PVD rigs. Every system has its own solution to overcome loss of vacuum in sand layers. Ask us about the possibilities.

What it is

This techniques involves the installation of artificial drainage paths or vertical drains into soft compressible soils with a lowering of the atmospheric pressure inside the drains to accelerate the consolidation process. The prefabricated vertical drain (PVD) used by Cofra for vacuum consolidation are specially designed to work effectively both under high settlements (i.e. under buckled or kinked conditions) and under the vacuum pressure.

How it works

Highly permeable soils like sand can adjust rapidly to loads and the corresponding compression / reduction in voids due to the ability to easily drain the excess porewater. Low permeable soils like clay and peat do not have this ability and show a delayed compression with the dissipation of the excess pore water. This process of dissipation of excess pore pressures, also known as consolidation, can take up to years depending on the thickness of the deposit. Vertical drains or also known as wick drains are used to shorten the dissipation path of the excess pore water and to accelerate the consolidation process to a few months or even weeks when the PVD is placed at close center to center distances.

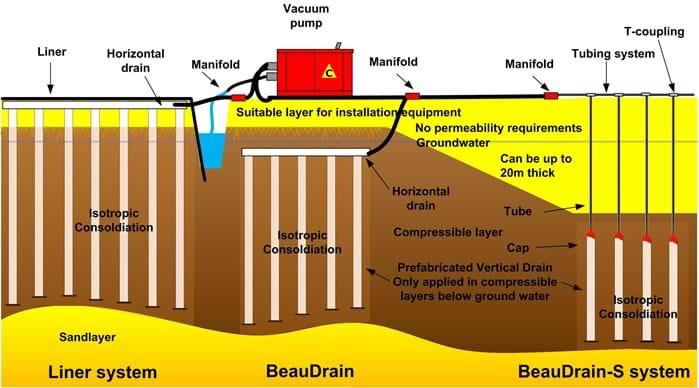

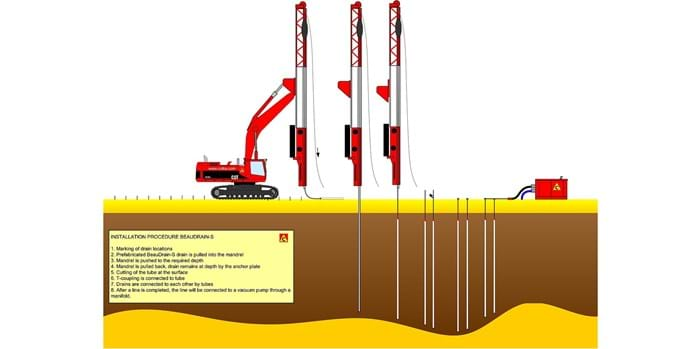

Vacuum consolidation acts, in principal, similar to prefabricated vertical drains (PVD) with surcharge. However an additional load is applied to the subsoil by lowering the atmospheric pressure inside the vertical drain. The applied vacuum pressure inside the system can be seen as an equivalent surcharge load. This means that the total applied pressure (surcharge load plus vacuum load) acts at the soil in order to accelerate the consolidation. This principle is the same for all vacuum methods. The difference between the methods is their application area caused by the ability of each system to seal the vacuum drains from ingress of air or permeable layers. The liner vacuum system uses a top liner and slurry walls around the area to seal the soil completely from air. The BeauDrain system installs the complete system below the ground water in the soft compressible soil with the help of a plough. BeauDrain-S uses tubes to cross any permeable layers and connects to a PVD in the soft material below the ground water. Please refer to the image below for more information.

Why it's used

Vacuum consolidation is often used to solve stability problems and create with the vacuum loading, which does not cause a driving moment for the instability, additional strength in the subsoil to accommodate for a faster surcharging schedule or a reduction in surcharge to limit the residual settlements. In countries with limited or very expensive surcharge, vacuum can be a good alternative to save costs. In rare cases vacuum consolidation is also used to limit horizontal deformations.

Application areas

Vacuum consolidation is used in the following markets:

- Infrastructure: Vacuum consolidation is for example used for the construction of embankments for roads, railways, the preloading of runways and aprons for airports and infilling of port areas on soft deposits where stability is a major issue of surcharge is scarce

- Dredging and land reclamation: Vacuum consolidation can be used when reclamations are constructed on soft deposits and horizontal deformations need to be reduced

- Mining: vacuum consolidation is highly suitable for the used in Tailing ponds to create strength without the application of surcharge. The vacuum system can be installed from a barge or specialized custom made tools.

- Construction: Vacuum consolidation is used to make green and brownfield areas suitable for construction of for example houses, warehouses and tank farms by reducing the residual settlement of the terrain

- Flood protection: vacuum consolidation is in the flood protection market to increase the stability of dikes and embankments during widening projects.

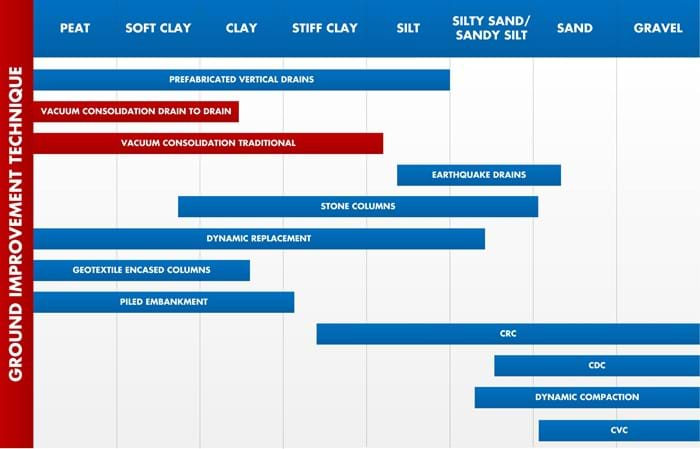

The following soil types are suitable for the use of vacuum consolidation:

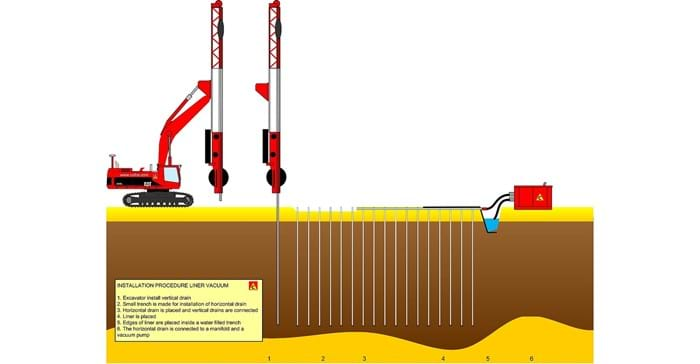

How is it installed - Liner vacuum system

For the liner vacuum system prefabricated vertical drains are installed using the wide range of stitchers, developed in-house by Cofra. The principal of installation of the vertical drainage is based on the insertion of a steel mandrel into the ground with a drain inside. The drain extension at the bottom of the mandrel can be connected to an anchor plate or stick to help the anchoring of the drain. Automatic anchoring systems are also available keeping the drain at depth during retraction of the mandrel. After the mandrel has reached the surface, the drain is cut and a new anchor plate is connected to the bottom of the next drain. The mandrel is pushed into and retracted from the ground through a system of cylinders and winches, which in turn are propelled by the excavators’ hydraulic system. After the drains are installed they are connected to a horizontal drain, this means that with the Cofra liner system no expensive drain sand is required. After the connection of all the drains, the area is covered with a liner and sealed from the atmosphere. If required special measures are taken at the sides of the vacuum area to prevent air leaks or excessive water ingress. The horizontal drains are connected to vacuum pumps for the application of the vacuum pressure.

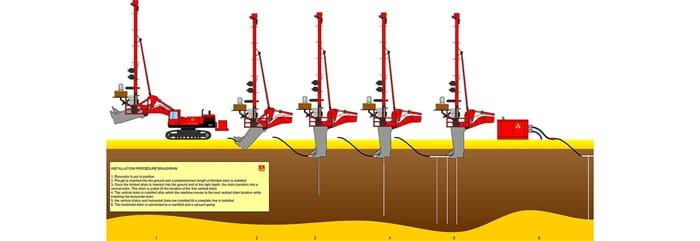

How is it installed - BeauDrain

The installation machine uses a specially designed plough to pull a horizontal collecting drain to a maximum depth of 2.5 m beneath the installation level (depending upon the thickness of the working platform and the groundwater level). As part of the production process, this horizontal drain is automatically connected to the top of a vertical drain installed in the same work operation. Finally, a strip of membrane is installed on top of the horizontal drain to improve the sealing between the atmosphere and the horizontal drain. After the installation of a predetermined number of drains, a blind section of the drain is led to the surface where it is connected to a vacuum pump.

How is it installed - BeauDrain-S

To prevent air leakage, a BeauDrain-S drain, prefabricated from a specially developed (MD88H) vertical drain, is coupled to a predetermined length of ethylene tubing. The ethylene hose is installed across the thickness of the working platform and, depending on the groundwater level, extended half a meter into the sealing clay or peat layer. The length of the hose is specially designed for each project or project area. After installation, only the ethylene hoses protrude above the installation platform. After the hoses have been cut to length, the BeauDrain-S drains are connected to each other in lines by means of couplings. These pipes are connected to a vacuum pump at the edge of the field via a manifold and collection hose.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering.

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets.

Technical Sales Cofra

For design questions or technical information.