Cofra is an experienced manufacturer and installer of Geolock. Over the years we have executed projects in Europe, North America and Asia. There are several ways to install the system, depending on project- and soil conditions. We all know them and our technicians are happy to inform and assist you on this, in pre-tender as well as installation phase.

What it is

Geolock cutoff wall is a waterproof barrier which consists of a patented lock construction, made of extruded HDPE, welded to 2.0 mm thick HDPE liner panels which are installed vertical in the subsoil. The lock system is equipped with a hydrophilic cord to guarantee water blockage, even at high depths / pressures.

How it works

HDPE material is resistant to a wide range of chemicals, including acids, salts, alkalis, alcohol, oils and hydrocarbons. It contains a proportion of carbon black, anti-oxidants and stabilizers. With the use of a HDPE lock including swelling cord welded to the liner an vertical impermeable seal is created. Cofra’s way of working complies with high standards on quality and safety. Our in-house laboratory is equipped to perform all tests required on manufacture and installed the material. Manufacture of Geolock panels takes place in a conditioned environment to assure quality. Welding the lock system to the liner requires a high level of expertise, both with regards to the welding process itself as well as to quality control.

Why it's used

The system is used to block (potentially) polluted groundwater flow at for instance waste disposal-, factory- and mining sites. In civil applications the system is used to block waterflow through dikes, dams and polder constructions. In cement-bentonite diaphragm walls it can be used in the top section to assure water tightness when deformations of wall are to be expected. As the material can be seen as gastight, one can keep this application in mind as well.

Application area

Geolock is used in the following markets:

Infrastructure: In Infrastructure Geolock is often used to create artificial polder for, for example, aquaducts.

Dredging and land reclamations: Geolock has been used to be able to lower the water table and accelerate consolidation.

Mining: Geolock is used to block contaminated waterflow

Pollution management: Geolock is installed around many landfill sites to prevent any leakage of pollutants.

Flood protection: In the flood protection market geolock is used to block waterflow in sandy layers and prevent the buildup of pressures in the polders behind the levees and dikes.

How it is installed

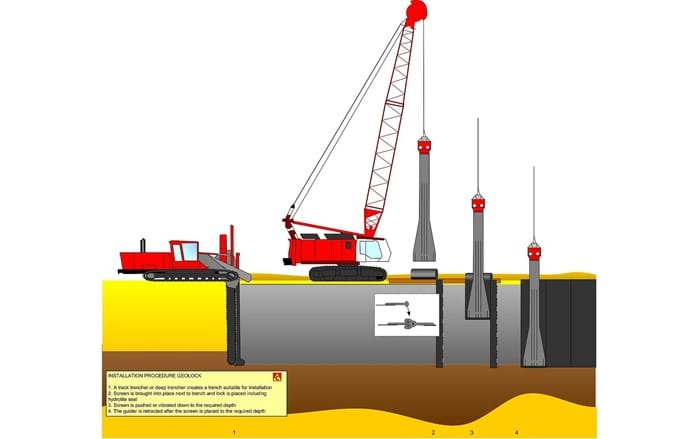

Geolock can be installed with the aid of a steel plate that drives the panels to the correct depth by means of a vibrating block. The system is only suitable for installation at a shallow depth in a relatively soft subsoil like soft clay sludge or peat.

In the case of installation at greater depths a bentonite wall is always constructed first in which the Geolock screen can be installed. The advantage of this method is that installation is possible in almost every type of soil and to a deeper depth. cofra has three methods available to create the bentonite wall. Up to 12 meters of depth a trencher can be used. Up to 20 meters a predrill and prepush technique can be used. For larger depth a diaphragm wall is required to be created. Below the installation method using a trencher.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering.

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets.

Technical Sales Cofra

For design questions or technical information.