Since the development of the synthetic prefabricated vertical drain (PVD) also known as wick drain in the late 1970ties, Cofra is worldwide one of the leading contractors. Cofra has installation rigs available for each soil type, varying from very soft soils to very stiff intermediate layers. Installing worldwide, we encounter depths of 3 to over 60 meter! Our heavy installation sets are the strongest in the world and able to penetrate 25 to 30MPa sands. For working offshore, we have the necessary experience and equipment. Our installation rigs are designed for containerized transport and thus easy to ship to any project location in the world.

What it is

This techniques involves the installation of artificial drainage paths or vertical drains into soft compressible soils. The prefabricated vertical drain (PVD) used by Cofra are specially designed to work effectively under high settlements (i.e. under buckled or kinked conditions). The vertical drains also come under other names like vertical band drains, strip drains or wick drains depending on the region you are in.

How it works

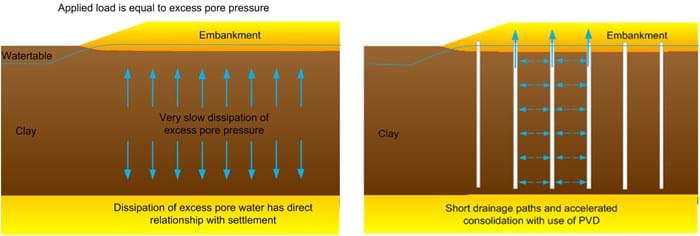

Highly permeable soils like sand can adjust rapidly to loads and the corresponding compression / reduction in voids due to the ability to easily drain the excess porewater. Low permeable soils like clay and peat do not have this ability and show a delayed compression with the dissipation of the excess pore water. This process of dissipation of excess pore pressures, also known as consolidation, can take up to years depending on the thickness of the deposit. Vertical drains or also known as wick drains are used to shorten the dissipation path of the excess pore water and to accelerate the consolidation process to a few months or even weeks when the PVD is placed at close center to center distances.

Why it's used

Vertical drains are used to accelerate the consolidation and reduce the consolidation period such that it fits within regular construction schedules. It also makes it possible to control and design for relative strict residual settlement requirements. The acceleration of the consolidation process has also the advantage that a faster lifting schedule of an embankment can be used. The strength of the subsoil has a relation with the degree of consolidation (adjustment of the subsoil to the placed load).

Application areas

Vertical drains are used in the following markets:

- Infrastructure: The drains are for example used for the construction of embankments for roads, railways, the preloading of runways and aprons for airports and infilling of port areas

- Dredging and land reclamation: Drains are used when reclamations are constructed on soft deposits

- Mining: Drains are used in Tailing ponds to accelerate consolidation or to increase the leaching effect in use embankments

- Construction: Drains are used to make green and brownfield areas suitable for construction of for example houses, warehouses and tank farms by reducing the residual settlement of the terrain

- Flood protection: Drains are used in the flood protection market to increase the stability of dikes and embankments during widening projects.

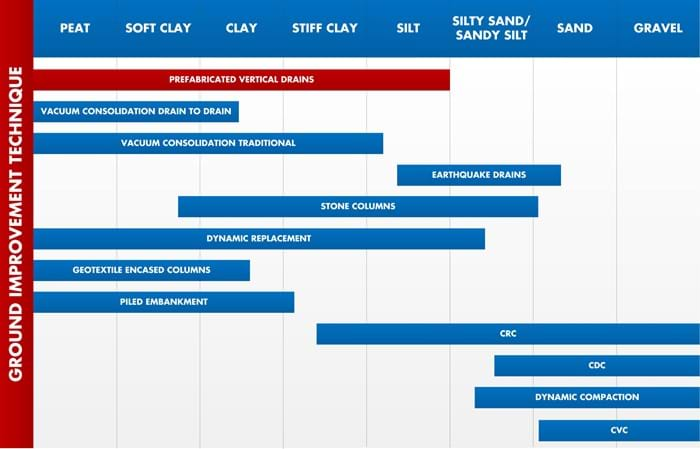

The following soil types are suitable for the use of PVD:

Find out more details about our offshore installation capabilities on this page

How it is installed

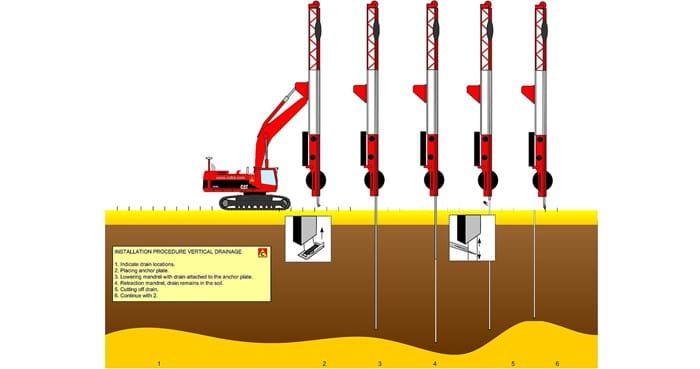

The prefabricated vertical band drains are installed using the wide range of stitchers, developed in-house by Cofra. The principal of installation of the vertical drainage is based on the insertion of a steel mandrel into the ground with a drain inside. The drain extension at the bottom of the mandrel can be connected to an anchor plate or stick to help the anchoring of the drain. Automatic anchoring systems are also available keeping the drain at depth during retraction of the mandrel. After the mandrel has reached the surface, the drain is cut and a new anchor plate is connected to the bottom of the next drain. The mandrel is pushed into and retracted from the ground through a system of cylinders and winches, which in turn are propelled by the excavators’ hydraulic system.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering.

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets.

Technical Sales Cofra

For design questions or technical information.