Compaction techniques form part of Cofra’s portfolio since 2005. Since that time we have compacted several tens of millions cubic meters with our compaction techniques. Our three compaction techniques are complementary to each other and are often used together on compaction projects. We use our Cofra Vibroflotation devices on reclamations where we need to compact a thickness larger than 7 to 9 meters. Our specialist are more than happy to tell you more about it

What it is

The Cofra Vibro Compaction (CVC) method, also referred to as Vibro flotation, is a technique used to densify loose granular materials at greater depths. A winged vibrator-section, with an eccentric weight, is located at the bottom of the vibroflot. A vibroflot consists of a vibrator and several followers to create a long needle that is penetrated into the soil. The vibrator generates horizontal vibrations that lead to a densified zone around the vibrator.

How it works

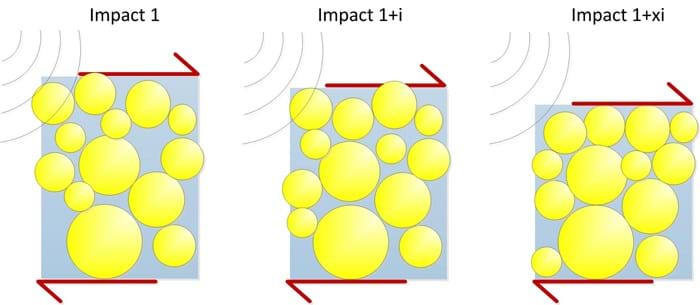

The compaction of the underground is initiated by high frequency vibrations, which lead to the rearrangement of the particles within the horizontal influence zone. These vibrations are generated at depth by the vibrator. It densifies a column of soil around the so-called flot.

The suitability of the method is more than other compaction techniques dependent on the grain size distribution and fines content. The material needs to be permeable enough to allow quick drainage of the added water during the compaction process. In practice this means less than 10% fines and less than 2% clay. During field trials at the start of a project, the horizontal influence zone is determined under different operational procedures and related to the project requirements. The outcome results in a center to center distance, also referred to as grid size.

Why it's used

Compaction is required to mitigate liquefaction risks or improve the bearing capacity and settlement behavior under loading of the underground. CVC compaction is often used on new reclamations to compact the subsoil up to requirements to avoid liquefaction under an earthquake.

The CVC results and required effort are related to the soil type, fines content and requirements. Applying Vibro- compaction will result in the following effects:

- Soil densification due to vibration and particles re‐organization

- Friction angle increase

- Stiffness increase

- Bearing capacity increase

- Liquefaction mitigation

- Limitation of settlement when applying load

Application area

Cofra Vibro Compaction is used in the following markets:

- Infrastructure: The CVC technique is for example used for the compaction of embankments for roads, railways, runways and aprons for airports and port areas. The compaction can in this case be related to liquefaction mitigation but also to improve the load settlement characteristics of the substrata under dynamic loading (transport of heavy equipment or reduce the long term impact of impacts)

- Dredging and land reclamation: CVC is often used to compact the deeper sections of reclamations up to specification

- Mining: CVC can be used to compact thick spoil deposits before the rehabilitation of an area.

- Construction: Cofra vibro compaction is used in the construction industry to mitigate liquefaction risks

- Liquefaction mitigation: CVC is used for liquefaction mitigation in areas where loose saturated granular soil occurs below a depth of 7 to 9 meters.

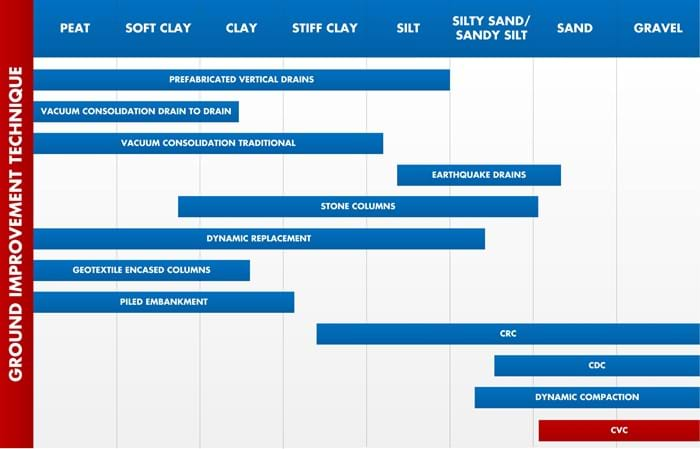

The following soil types are suitable for the use of CVC:

How it is installed

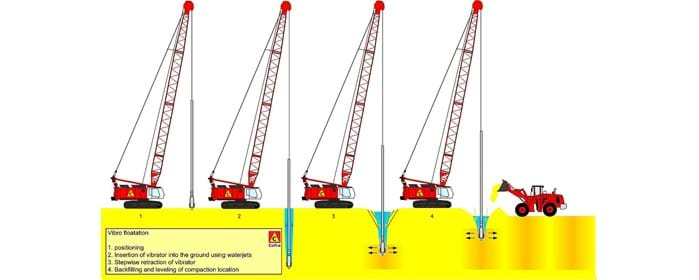

The CVC method is executed by driving a large vibrating needle, called vibroflot, into the ground by means of water- and/or air-jetting. At depth the compaction phase starts and the vibroflot is either gradually, or in steps withdrawn, while vibrating heavily. The vibrations are generated by the winged vibrator-section, with an eccentric weight located at the bottom of the vibroflot. While compacting, granular material is added from the surface to fill the voids.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering.

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets.

Technical Sales Cofra

For design questions or technical information.