Compaction techniques form part of Cofra’s portfolio since 2005. Since that time we have compacted several tens of millions cubic meters with our compaction techniques. Our three compaction techniques are complementary to each other and are often used together on compaction projects. Our CRC rollers have the lowest depth of influence from our compaction techniques and are able to compact the top 2 to 3 meters of the subsoil and perform amongst other application areas often the ironing pass after vibro compaction works. Our specialists are more than happy to tell you more about it.

What it is

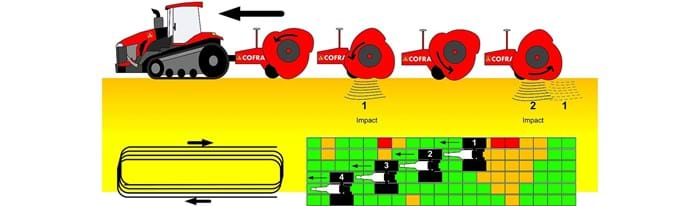

The Cofra Roller Compaction (CRC) method, also referred to as High Energy Impact Compaction (HEIC), is a technique that densifies loose granular materials up to a depth of 2 to 3 meters below the surface by pulling a non-circular roller over the surface of an area.

How it works

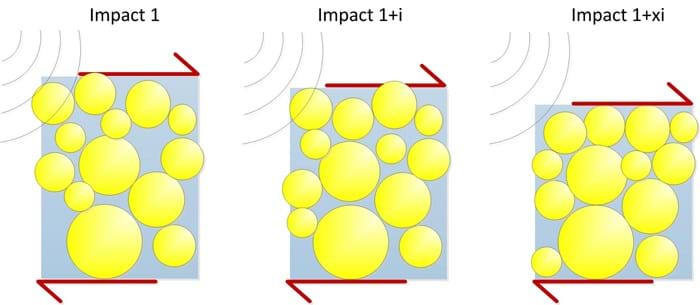

The compaction of the underground is initiated by vibrations, which lead to the rearrangement of the particles. These vibrations are generated from the impact of a weight onto the surface. The CRC method is in essence a light form of dynamic compaction in which densification is achieved by lifting and dropping a weight from a specified height. The shape of the non-circular drums of the CRC equipment cause in this case the lifting and dropping motion of the drum weight as the equipment travels over the site.

Why it's used

Compaction is required to mitigate liquefaction risks or improve the bearing capacity and settlement behavior under loading of the underground. The roller compaction is, due to it’s shallow application, mainly used to improve the bearing and settlement characteristics of the top layers.

Applying CRC will result in the following effects:

- Soil densification due to vibration and particles re‐organization

- Friction angle increase

- Stiffness increase

- Bearing capacity increase (Modified dry densities of 95% and 98% MDD can be reached with the system)

- Liquefaction mitigation

- Limitation of settlement when applying load

Application area

Cofra roller compaction is used in the following markets:

- Infrastructure: The roller is for example used for the compaction of embankments for roads, railways, runways and aprons for airports and port areas

- Dredging and land reclamation: CRC is often used to compact the top layer of the reclamation up to specification

- Mining: CRC can be used to compact roadways for the heavy mining trucks or to allow for higher production in the filling of spoils.

- Construction: Cofra Roller compaction is used in the construction to compact terrains but also to investigate the areas for weak spots that need treatment

- Liquefaction mitigation: CRC is used for liquefaction mitigation in areas where loose saturated granular soil occurs near the surface

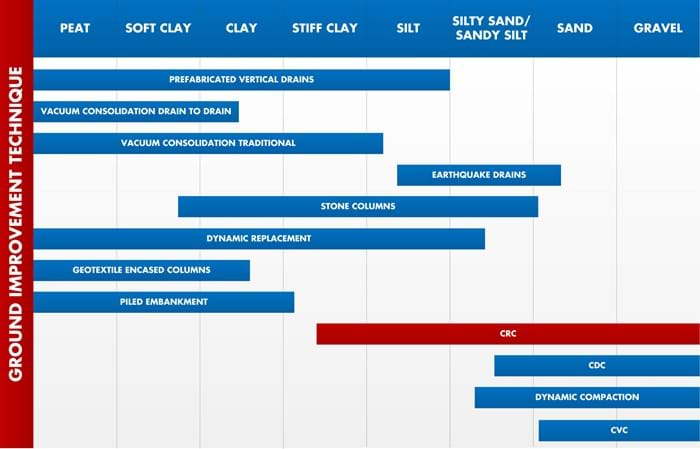

The following soil types are suitable for the use of CRC:

How it is installed

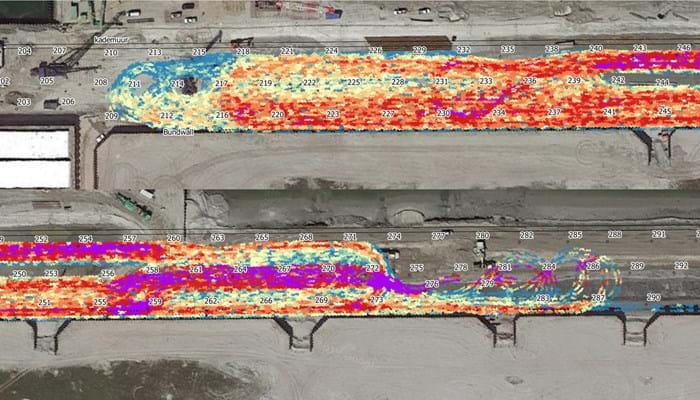

The roller is pulled at speeds between 10-15 km/h to generate the most optimal effect. The method has the highest surface production rate of all compaction methods known today, with a coverage in a single pass over 100.000m2 a day. The CRC technique compacts the underground fast, homogeneously and with high accuracy due to the use of a GPS guided monitoring system. The main parameter of interest is the deceleration of the impact, which is related to the compaction level of the subsoil. Overviews of the deceleration, as schematically indicated in the image below, create insight into the areas that require further attention.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets

Technical Sales Cofra

For design questions or technical information