Cofra is an highly experienced installer of PE geomembranes with more than 25 years of experience. We are one of the largest installers in the Netherlands on waste disposal sites and in the civil application of KIWA-certified 2.0 mm HDPE geomembranes. With help of our network, in-house expertise and engineering department we can provide you with assistance in the design of the capping structure, get you in contact with industry experts and quality assurance agencies or brainstorm with you about out of the box ideas. Please get in contact if you would like to know more about what we can do for you.

What it is

HDPE membrane is resistant to a large number of chemicals, including acids, salts, alkalis, alcohol, oils and hydrocarbons that occur in practice. The HDPE installed by Cofra complies with the requirements summarized in the BRL-K 538/01. High-Density PolyEthylene (HDPE) liner consists of a proportion of carbon black, anti-oxidants and stabilizers. It is the most commonly used membrane for the sealing of landfills, dredging tips, lagoons and water reservoirs.

How it works

With the welding of the liner an impermeable seal is created resistance to most chemicals. Monitoring and process control are essential when using HDPE liner for separation purposes. Cofra’s way of working complies with all regulations for HDPE quality control. Our in-house laboratory is equipped to perform all tests required on the liners installed.

Why it's used

HDPE liners are most often used to separate contaminated material from the surrounding areas and block any water flow.

Application area

Liners are used in the following markets:

Infrastructure: Liners are used in infrastructure projects to seal contaminated material when used in embankments or to seal excavations from water inflow.

Mining: Liners are used to seal any contaminated material from the environment

Pollution management: Liners are used to seal any contaminated material from the environment

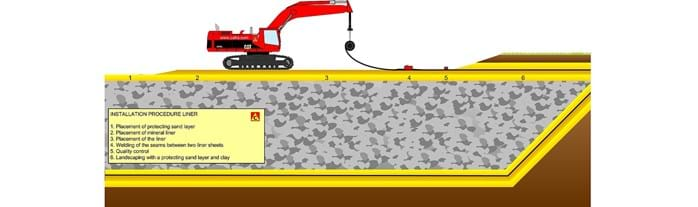

How it is installed

The membrane is unrolled with a so called “spreader bar”, connected to a hydraulic excavator. The membrane strips are laid with an overlap so that they can be welded together. Cofra uses two different welding methods. Automatic welding with a hot bolt or wedge welding machine or channel welding and manual welding with an extrusion welding machine.

Automatic welding is used for making long weld seams between the membrane strips. Extrusion welding is used for seams that cannot be produced mechanically, such as details, repairs and lead-through constructions. All welding methods require a high level of expertise, both with regard to implementation and in terms of checking to guarantee optimal weld quality. Before the start of a job, both the competence of the technicians and the function and set-up of the welding machines are checked by doing test welds. These are checked daily in a mobile laboratory.

The final checking of the welding comprises an inspection to determine the sealing of the weld. In the case of channel welds the welds are squeezed using air pressure. In the case of extrusion welds the welds are tested using a vacuum or flashing. Inspection is performed by an independent accredited inspection agency.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering.

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets.

Technical Sales Cofra

For design questions or technical information.