Stone columns are widely used as ground improvement method for unsuitable soils to improve its bearing capacity and limit settlements. Cofra has the capability to install stone columns using special rigs attached to our standard base units. Ask us for the possibilities in applying stone columns for your project.

What it is

Stone columns are densified columns of granular material installed in fine grained material to either transfer load down to the bearing strata or increase the strength of the soil to increase the resistance against liquefaction.

How it works

The insertion of granular columns improves the overall characteristics of the soils. The introduction of high friction material into the soil whilst displacing and tensioning the soil leads to overall higher strength and bearing capacity.

In compressible material creates a consolidation process in which the columns act as a drainage paths due to their high permeability. This leads to a reduction in settlements and residual settlements.

During an earthquake event they give support and strength to the soil mass. They are able to reduce the excess pore pressure developing during the earthquake event.

A stone columns application may show more residual settlement when compared to a piled solution, but less residual settlement when compared to a consolidation solution. As no geotextile support is used, the can only be applied in soils with sufficient lateral constraint (i.e. Su>15kPa) to prevent excessive overconsumption of stone.

Why it's used

Stone columns are used to increase the shear strength of the soil and as such improve the resistance against liquefaction. They are used when the soil is liquefiable, but too silty to use the compaction techniques to improve the properties. The columns are also used to increase the bearing capacity and limit the settlements by transferring part of the applied load down to the bearing strata.

Application area

Stone columns are used in the following markets:

Infrastructure: The Cofra Stone column technique is used for the fast construction of embankments for roads, railways, runways and aprons for airports and port areas.

Dredging and land reclamation: Stone columns can be used to avoid the use of sand keys and prevent liquefaction of silty sand section inside the reclamation or subsoil

Mining: Cofra stone columns can be used to create additional strength in the subsoil to construct infrastructure on top of sandy tailings.

Construction: The stone columns are used for the fast construction of embankments for construction sites or as foundation for warehouse floors

Liquefaction mitigation: Stone columns are often used to mitigate the effects of liquefaction in silty soils

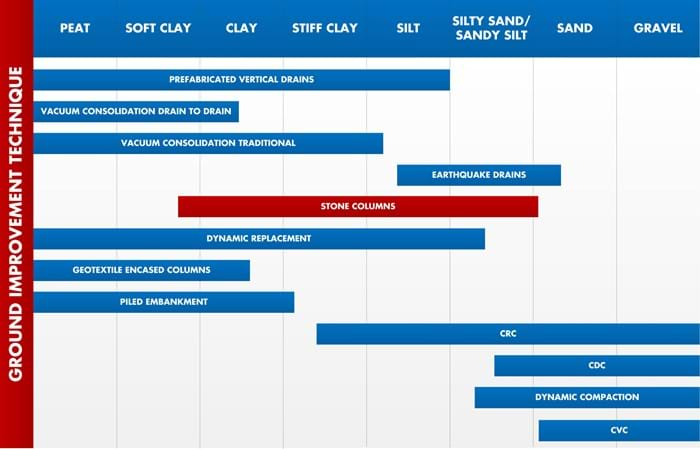

The following soil types are suitable for stone columns:

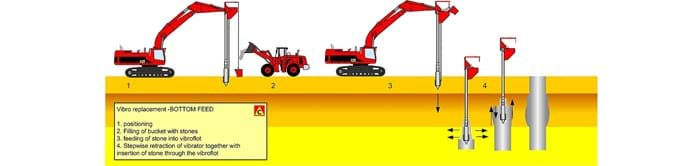

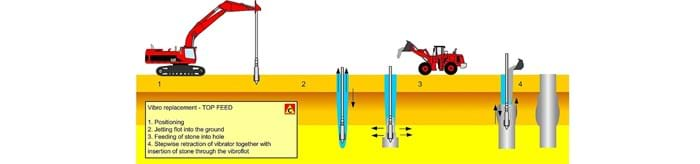

How it is installed

Cofra Stone Columns are installed using vibratory flots mounted to hydraulic excavators. The flot is inserted into the ground till design depth using water and air jets. At the design depth granular material is added into the void created. This can be done by a bottom feed method in which the granular material is added at the top of the vibroflot and guided till the tip using a feeding pipe or by the top feed method in which the granular material is added at the surface and falls in the created void.

In both methods the flot is moved up and down in 0.5m steps during the creation of the column. At the reinserting of the flot into the created column the material is pushed to the sides after which new material can be added. The next 0.5m section is treated after the section that is treated reaches the required theoretical diameter or set limit values.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering.

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets.

Technical Sales Cofra

For design questions or technical information.