Dynamic Compaction is a compaction method which has been around for more than 60 years. It is a simple method with a great impact. A pounder is dropped in free fall from a specified height onto the surface to compact the soil. Cofra uses this technique in situations where our other compaction systems do not meet the criteria in an economical way or where our other methods are not allowed. With a depth of influence of over 12 meters, the technique has a larger depth of influence when compared to our CDC compaction hammers. Cofra uses the dynamic compaction with state of art monitoring systems to make the process as controlled as possible.

What it is

Dynamic Compaction (DC) is a technique that densifies loose granular materials up to a depth of 10 to 12 meters below the surface by repeatedly dropping a pounder of 10 to 20 tons from a height of 10 to 25m onto the surface.

How it works

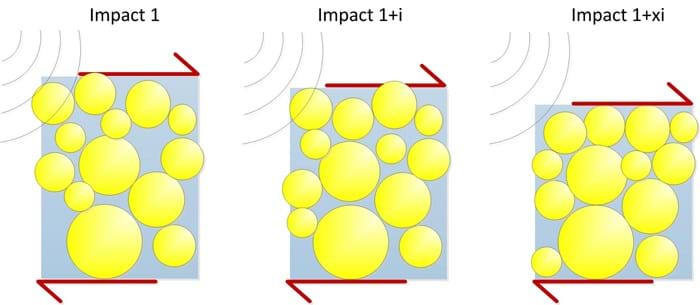

The compaction of the underground is initiated by vibrations, which lead to the rearrangement of the particles. These vibrations are generated from the impact of a weight onto the surface.

With the impact of the pounder densification is achieved and a large depression is created. The depression should not extend into the watertable, blocking an effect transfer of the impact energy into the ground. Depending on the requirements, 4 to 10 blows are given on each location. A wide compaction grid is used in several phases.

The compaction results are, amongst others, dependent on the soil type, fines content and requirements. An assessment of the local soil by a compaction expert is therefore highly recommended. The depth of influence can be limited by density differences in the subsoil. If the situation is ideal, effects can be measured up to 12 meters deep. Improvements of up to qc=30MPa have often been achieved in the top 7-8 meters of the soil column.

Why it's used

Compaction is required to mitigate liquefaction risks or improve the bearing capacity and settlement behavior under loading of the underground. Dynamic compaction is often used on new reclamations to compact the subsoil up to requirements to avoid liquefaction under an earthquake. The solution is also in high demand to improve the bearing and settlement characteristics of the top layers .

Applying Dynamic Compaction will result in the following effects:

- Soil densification due to vibration and particles re‐organization

- Friction angle increase

- Stiffness increase

- Bearing capacity increase

- Liquefaction mitigation

- Limitation of settlement when applying load

Application area

Dynamic Compaction is used in the following markets (click on the specific market for more information):

- Infrastructure: The DC technique is for example used for the compaction of embankments for roads, railways, runways and aprons for airports and port areas. The compaction can in this case be related to liquefaction mitigation but also to improve the load settlement characteristics of the substrata under dynamic loading (transport of heavy equipment or reduce the long term impact of impacts)

- Dredging and land reclamation: DC is often used to compact reclamations up to specification

- Mining: DC can be used to compact roadways for the heavy mining trucks or to allow for higher production in the filling of spoils.

- Construction: Dynamic compaction is used in the construction industry to compact terrains.

- Liquefaction mitigation: DC is used for liquefaction mitigation in areas where loose saturated granular soil occurs up to a depth of 12 meters

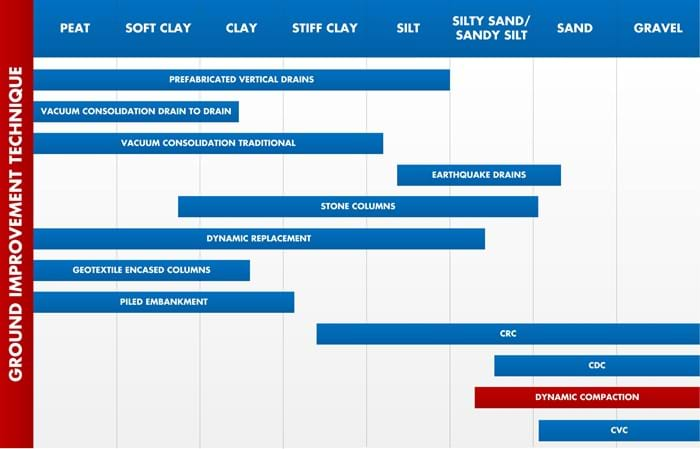

The following soil types are suitable for the use of DC:

How it is installed

The operational process of Dynamic Compaction consists of placing the pounder on the marked location. After positioning, the pounder is lifted and released from the predetermined height. After impact the pounder is lifted for a following drop. This process is repeated until the stop criteria set by our geotechnical engineer are met. These stop criteria are determined during field trials investigating the the number of blows by print, the drop height, the pounder weight and the number of phases.

Contact us (regional contacts on our contact page)

Business development Cofra

For new opportunities or partnering.

Estimation Department Cofra

If you require a quotation or need a budget for your project for any country in world outside our home markets.

Technical Sales Cofra

For design questions or technical information.